Urethane Casting Service

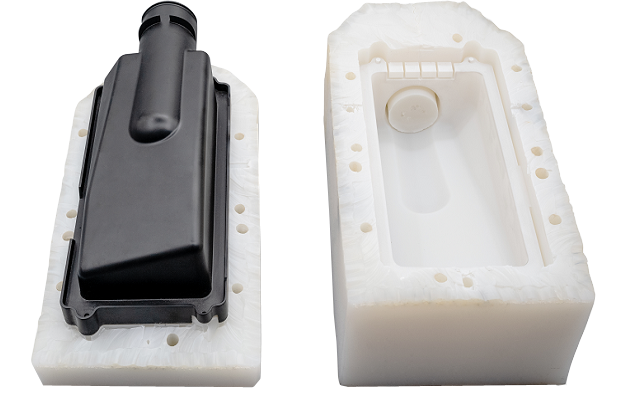

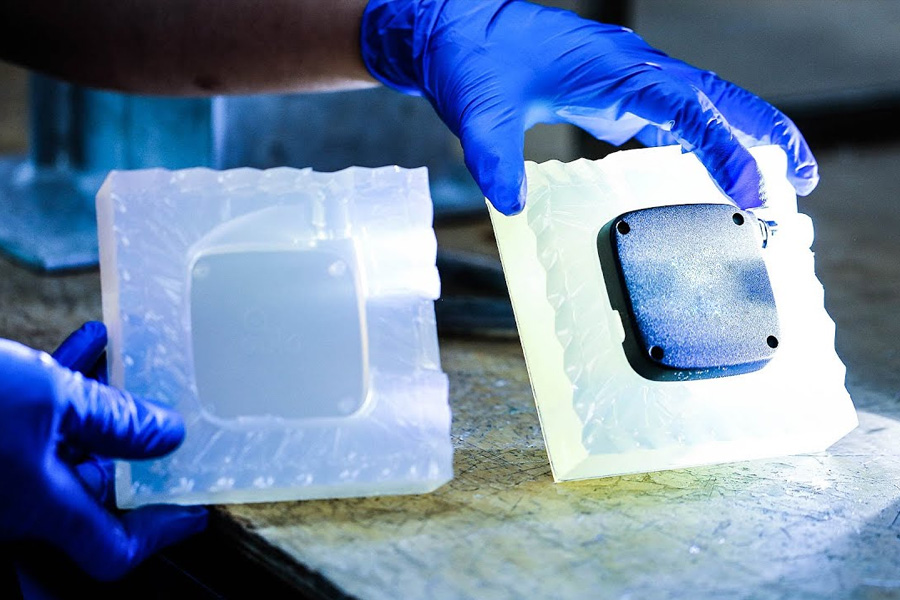

Urethane casting service is a manufacturing process that uses silicone molds to replicate parts and products using urethane materials, ideal for low-volume production and prototyping.

Rapid prototyping and production

Fully inspected before delivery

MOQ 1 PC and as fast as 2 days delivery

Start Get A Quote

All drawings are secure and confidential.

Urethane Casting Process

Rapid Mock-up

As Fast As 2 Days

Urethane Casting

Low Volume Urethane Casting

Without Tooling Fee

Surface Finishing

Painting, Silk Screen, Laser Marking.

Urethane Casting Tolerance

Urethane casting is a fabrication process that uses silicone molds to produce production-grade elastomeric parts with 10-200 units.

Typically ISO 2768-m is used as manufacturing standard and a shrinkage rate of +0.15% can be expected due to

thermal expansion of the liquid, and the response of the flexible mold.

Linear Dimension

Limits for nominal lengths

F (fine)

0.5mm to 3mm

±0.1mm

Over 3mm up to 6mm

±0.1mm

Over 6mm up to 30mm

±0.2mm

Over 30mm up to 120mm

±0.3mm

Over 120mm up to 400mm

±0.5mm

Over 400mm up to 1000mm

±0.8mm

Over 1000mm up to 2000mm

±1.mm

Urethane Casting Materials

Plastic

ABS-Like

Acrylic-Like

Nylon-Like

Acrylic-Like

PP-Like

Rubber-Like

Clear Rubber-Like

Surface Finishing

We can instantly quote a wide variety of post-machining surface finishes.

Painting

See details

Powder Coating

See details

Silk Screen

See details

Laser Marking

See details

Our Customers speak for us