Custom Sheet Metal Fabrication Services

Upload your CAD drawing and start the custom sheet metal fabrication process with a quote. Competitively priced delivery in as few as 3 days on over 10 types of materials and surface finishes.

Sheet metal thickness 0.5 - 10mm

More than 10 kind of materials and finishes are available

Fastest delivery time 3 working days

Start Get A Quote

All drawings are secure and confidential.

Sheet Metal Fabrication Process

Laser Cutting

Wire Cutting, EDM, CNC Machining, etc

Bending

V-Bending, U-Bending, Multi-angle

Welding

Gas Tungsten Arc Welding, Resistance Spot Welding

Surface Finish

Sandblasting, Anodizing,

Electroplating, Polishing, etc

What is Sheet Metal Fabrication?

Sheet metal fabrication is the process of shaping and manipulating thin sheets of metal to create various products or components.

YCX performs the sheet metal fabrication process through a series of steps. It all starts with the customer and us establishing contact. We then receive the customer’s CAD drawing, and then get to work. This systematic method is the secret behind our provision of the best sheet metal fabrication services.

We boast of fast sheet metal fabrication services. Our list of sheet metal materials comprises of aluminum, stainless steel, steel alloy, brass, and copper. The subtypes of these materials include aluminum 5052, steel alloy SPCC, stainless steel 304, and copper C110.

You can rely on YCX for the best metal fabrication services because we have an experienced team of sheet metal fabricators. If you are looking for a sheet metal supplier, we can be your reliable partner. We cater for all production runs – high volume production runs and low volume production runs alike.

Sheet Metal Tolerance

If not otherwise specified on the technical drawing, all parts will be machined to ISO 2768 tolerance standards below. Generally you can choose ISO 2768-m, ISO 2768-f or specify more tighter tolerances in your 2D technical drawings.

Types

Value

Edge to edge, single surface

±0.010″

Edge to hole, single surface

±0.010″

Hole to hole, single surface

±0.005″

Bend to edge / hole, single surface

±0.015″

Bend to Bend

±0.020″

Edge to feature, multiple surface

±0.030″

Over formed part, multiple surface

±0.030″

Bend anglev

±1°

Sheet Metal Materials

YCX offers a wide range of sheet metal materials. Our aim is to always have a stockpile so big that a project gets up and running within the shortest time possible.

Materials

Subtypes

Aluminum

Stainless Steel

304

Steel Alloy

Brass

Copper

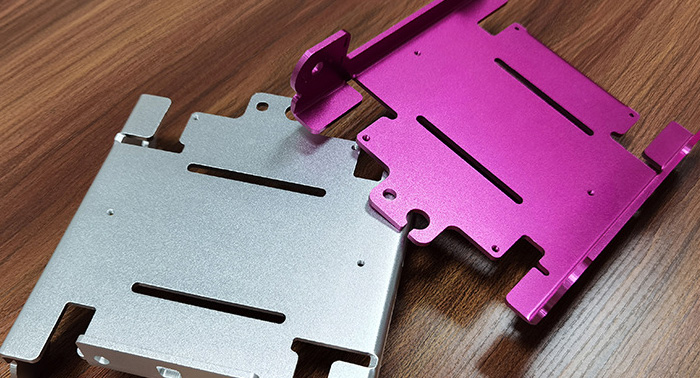

Sheet Metal Surface Finishes

We can instantly quote a wide variety of post-machining surface finishes.

Anodizing

YCX offers a wide range of sheet metal materials. Our aim is to always have a stockpile so big that a project gets up and running within the shortest time possible.

Learn More

Bead Blasting

Bombarding the sheet metal surface with special abrasive matter results in a smooth surface with a matte appearance and devoid of imperfections.

Learn More

Powder Coating

This sheet metal finishing process whereby the electrostatic application of special powdered paint followed by curing creates an attractive and protective coating on the sheet metal.

Learn More

Electroplating

The electroplating process involves the deposition of a thin layer of zinc or another metal on aluminum or any other base metal for a shiny and smooth result.

Learn More

Polishing

Sheet metal polishing is a technique employed to attain a glossy and reflective appearance on the metal surface through a meticulous smoothing process.

Learn More

Brushing

In the brushing process, abrasive brushes move on the sheet metal surface unidirectionally to give a matte finish that is characterized by visible lines.

Learn More

Alodine

In Alodine, also called chromate conversion coating, a chemical solution with chromate compounds is applied on the sheet metal to produce an iridescent appearance.

Learn More

Copper plating

In copper plating sheet metal fabrication finish, we electroplate the sheet metal with a thin layer of copper for a distinctive metallic appearance. Request a free quote!

Learn More

Screen Printing

Screen printing applies ink through a stencil onto sheet metal, creating intricate custom graphics, text, or images.

Learn More

Chrome plating

This is an electroplating process of putting a very thin layer (0.3-1 µm) of chromium on top of a metal or alloy substrate.

Learn More

Galvanization

This is the process of applying a zinc coat on sheet metal to increase its corrosion resistance. It gives the sheet metal a uniform grey look.

Learn More

Our Customers speak for us