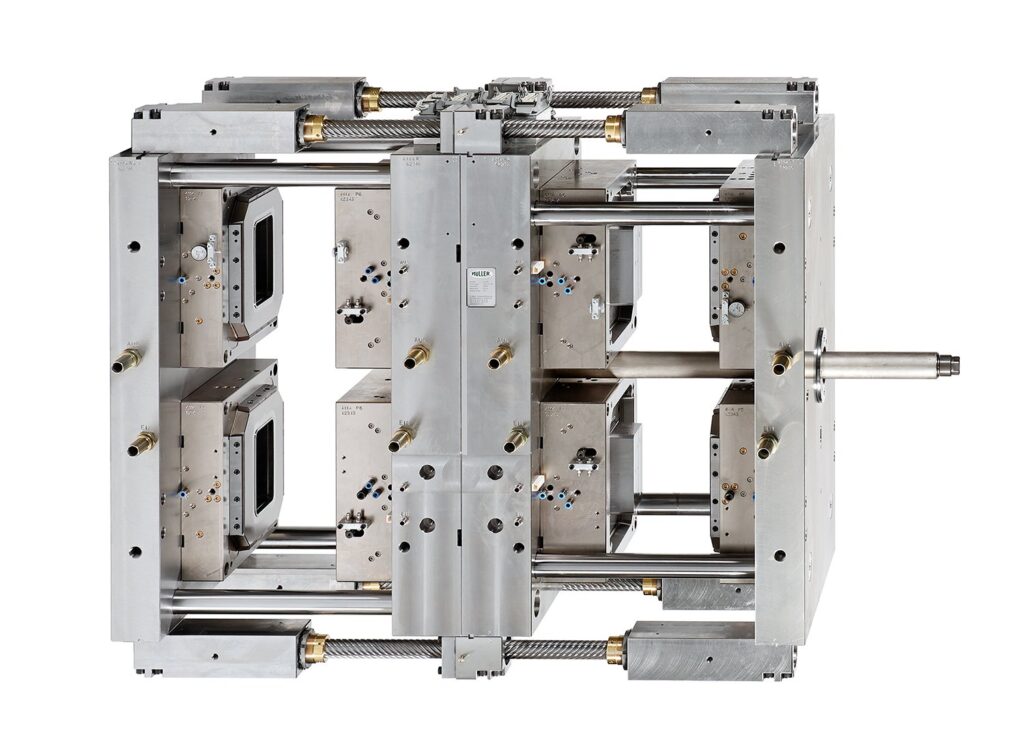

Mold Making Capabities

YCX-Mold provides rapid injection molding with aluminum and steel tooling, various mold types, a wide range of materials, and additional services, ensuring quick turnaround and scalability for low to high-volume production.

Custom Manufacturing On Demand

The design department has a group of professional senior mould-design engineers who can find the main features of the products and seize the points to decide the plan of mould design after having a clear understanding of customers’ products.

They make analysis of the products, design mould, design processing routes and manufacture mould parts by using UG, SOLIDWORKS, Pro-E and CAD. The advanced design and manufacturing software can simulate the whole process of mould manufacturing and is present in every step of mould design, process planning, part processing, part inspection, mould assembly and product formation.

They provide customers with high-quality, low-cost and short-cycle mould design plan according to customers’ technical requirements. They proved their great strength with highly-sophisticated technology which combines the excellent Mold flow Adviser technology with the hot runner technology.

Tooling Export

Tools manufactured for export builtto globally recognized interationalstandards and quality.

Tools manufactured for export builtto globally recognized interationalstandards and quality.

Guarantee tools to run in your facilityand have trouble shooting team toback up that guarantee.

Tooling Project Process Flow

Customer Request

Drawing review & Quote

PO negotiation & Release

DFM/CAE ( if required )

Mould Design (2D&3D )

Customer Confimmation

Inner Review MeetingProcess Planning

1-3 Days

1-3 Days

Injection Molding

Heat Treatment Report

Steel Certificate

Steel Certificate

Mold Inspection/Shipment

Cstomer Approval

Mold Trial & Sample Shipment

Mold Assemble & Surface Treatment

Precision MachiningCNC/EDM/EDW

Heat Treatment

Rough Machining Driling/Grinding

4-8 Weeks

Mold FinalInspection Report

1. Trial Processing

Report

2. Steel & Sample

Inspection Report

3. Mold Trial Review

Report

Mold Process

Weekly Report

Plastic Injection Flow Chart

Sample

Preparation

Confirm

Appraisal

Preparation

Scheduling

Mold Development

Complete & Delivery

Pilot Run

Approve

Try Shoot

Tools Modify

Try Shoot & Check Quality

YCX Tooling Solution

Our 15800m? facility producesmore than 100 million partsannually using 50+ plastic injectionmolding machines.

Robots on every press and variouslevels of automation.

Specializing in complex designs,tight tolerances, and high cosmetic parts.

Industries we serve

For 21 years, we have provided high-quality on-demand manufacturing services to various fields around the world.

Aerospace

Medical

Automotive

Manufacturing

Robotics

Energy

Agriculture

Electronics

Telecom

Construction

Oil & Gas

Sports

Our Customers speak for us