Injection Molding Services

YCX-Mold offer injection molding services for thermoplastic materials, with options for various surface finishes and complex geometries. Our capabilities include DFM feedback and fast turnaround times for low and high volume production runs.

Rapid prototyping and production

Insert molding, Overmold services are available

IOS 9001 : 2015

Start Get A Quote

All drawings are secure and confidential.

Injection Molding Processes

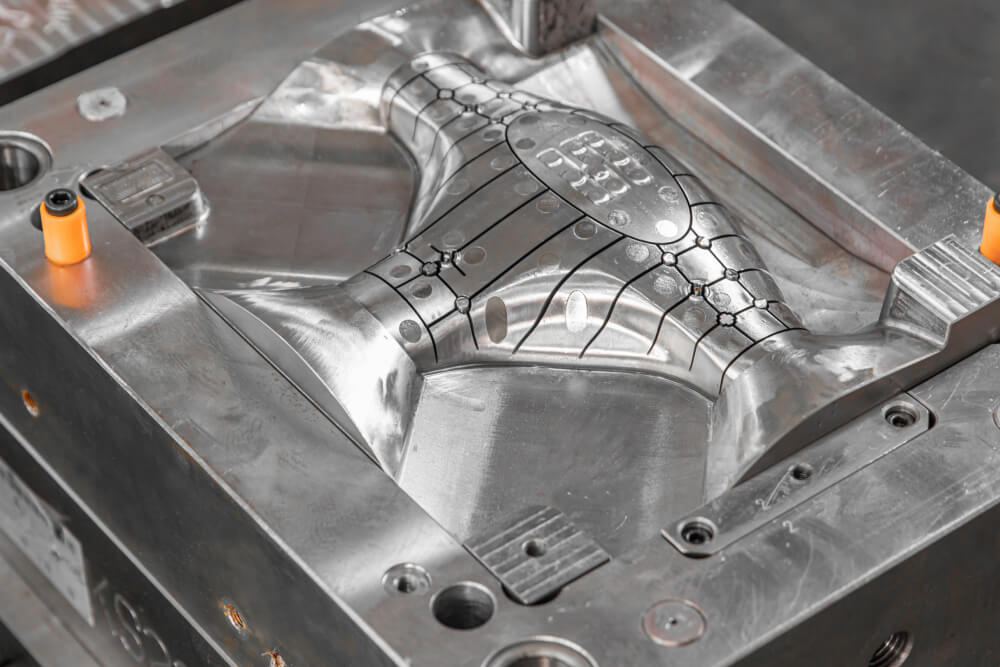

Plastic Injection Molds

we can create custom molds tailored to your specific needs, whether it’s for injection molding, die-casting, or other manufacturing processes.

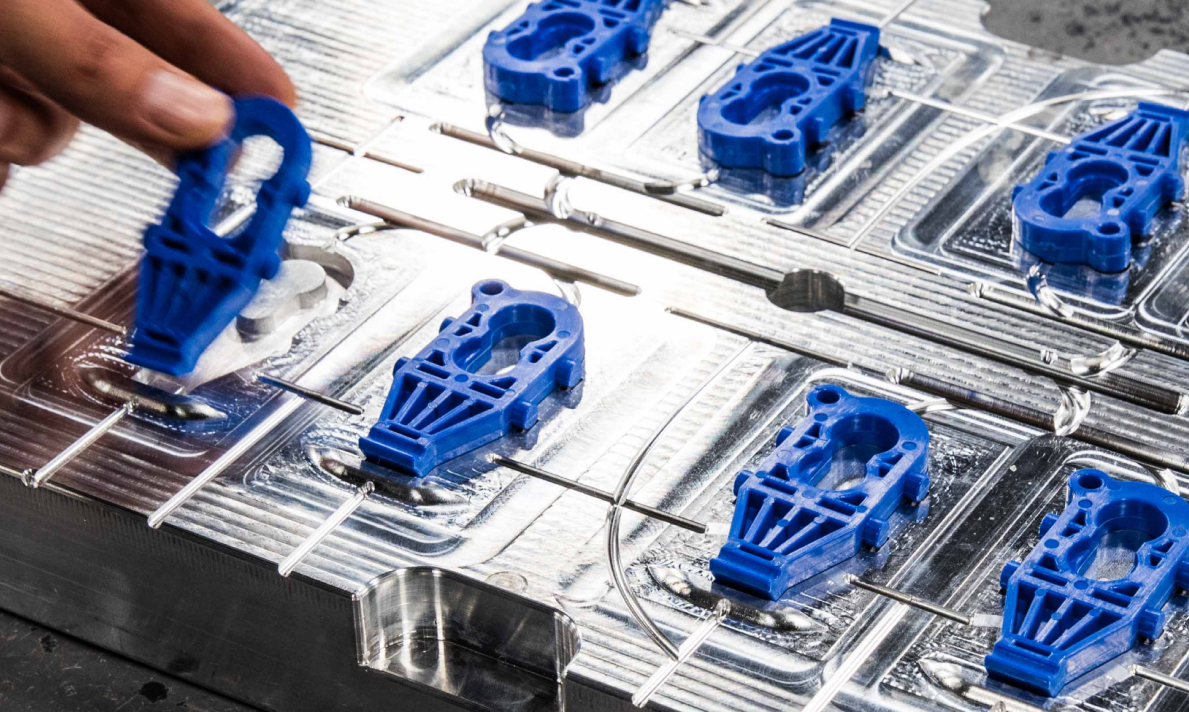

Plastic Injection Molding

YCX Mold offers rapid prototyping services, allowing you to quickly test and iterate on your mold design before committing to full-scale production.

Overmolding

We can provide design assistance to optimize your product for overmolding, helping you achieve the desired results.

Insert Molding

We can create insert-molded parts tailored to your specific design and application requirements.

How to work with YCX-Mold?

1. Upload your design

Upload your parts to our platform to have your project reviewed by our team

2. Receive a quote

Your account manager will work with our technical team and manufacturing partners to send you a quote within 48 hours

3. DFM & tool approval

Receive extensive Design For Manufacturing analysis to approve before construction of your tool begins

4. Receive T1 samples

We send you a golden sample for approval before starting production

5. Production & delivery

We produce your parts to match the golden sample & deliver them to you

6. Reorder as required

You can easily reorder parts by contacting your account manager

Injection Molding from Prototyping to Production

Rapid Prototyping

Ideal for rapid prototyping and low-volume production

Tool shot life – 1k to 100k units

Fast turnaround and cost-efficient construction

Aluminum or steel

Production

Longer-lasting tooling for larger volumes

Tool shot life – 100k to 1M units

Automated production for cost-efficiency at higher volumes

Hardened steel for longer life and a scalable unit price

Injection Molding Materials

Property

Materials

Impact resistant

ABS, PMMA, PVC, PE, PC

Wear-resistant

POM, PEEK, UHMW

Dimensional stability

ABS, PMMA, PVC, PE, PC

Chemical resistance

PEEK, PP, PBT, PE, LDPE, PA

Rubber like

TPU, TPE, Silicone

Cost-efficient

PP, HDPE, LDPE

Cosmetic

ABS, PC, HIPS

We can source any other material on request, Get A Quote Now.

Injection Molding Surface Finishes

SPI surface finishes

We offer any type of SPI surface finish, such as A-1, D-2 or D-3.

VDI surface finishes

We offer any type of VDI surface finish, such as VDI28, VDI30 or VDI 33.

Secondary operations

Inserts

Pad Printing

Painting

Silk screening

Ultrasonic welding

Laser engraving

UV coating

3D Textures

Hot stamping

Post-mold machining

Our Customers speak for us