CNC Machining Services

YCX is dedicated to delivering perfect designs to not only meet the customer requirements but to exceed them in real time.

Rapid prototyping and production

Fully inspected before delivery

MOQ 1 PC and as fast as 3 days delivery

Start Get A Quote

All drawings are secure and confidential.

What is CNC Machining?

CNC or Computer Numerical Control machining is a digital manufacturing technology that provides high accuracy parts directly from Computer Aided Design (CAD) files. CNC machining provides for high reliability and accuracy of produced parts by removal process which reduces the solid object material to desired end product.

This is done by a Computer Numerical Control machine. These machines are able to rotate tools around various axes, usually 3,4 and 4 axis.

Our CNC machines are operated by highly skilled and trained machinists who program tool paths in accordance with the geometry requirements of the finished machined parts. this is made possible with the availability of a computer Aided Design file which provides all the required information. Our company offers unique CNC bids in addition to services for several metal and plastic types.

Types Of Our CNC machining Process

We have CNC machining centers like horizontal turning centers and vertical with spindles for tight tolerance milling and turning.

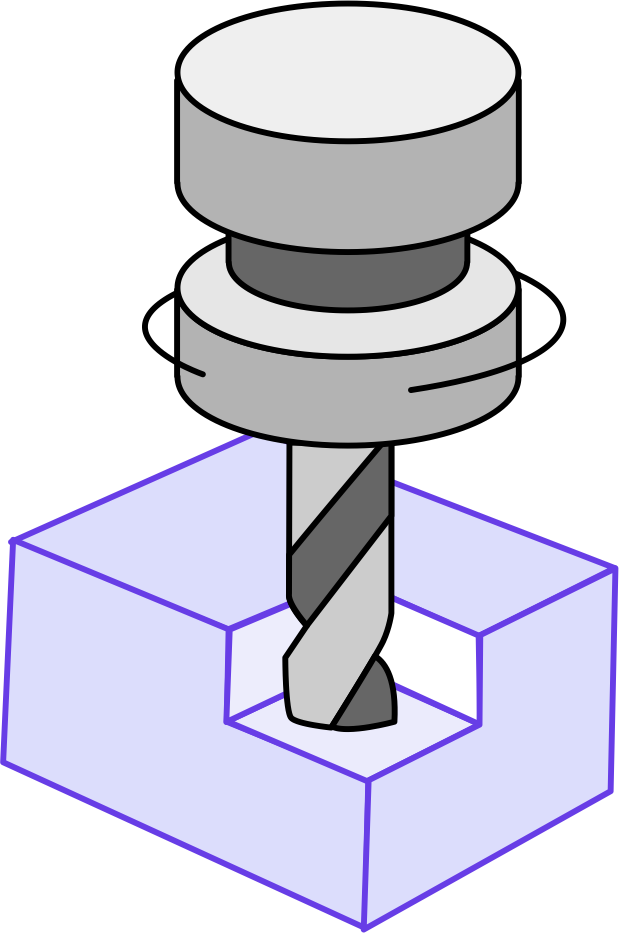

3-Axis Milling

3-axis milling are for low budget as they have lower maintenance and investment costs. The machines are good for simple parts with simple geometry with no complex features.

4-Axis CNC Milling

4-axis CNC machines are better for curved surfaces and features. These machines are better for parts with high tolerance and when working on a piece with features with multiple sides. It is also good for high volume production as it is highly efficient.

5-Axis CNC Milling

5-axis CNC Milling is majorly for complex geometries and high volume production.

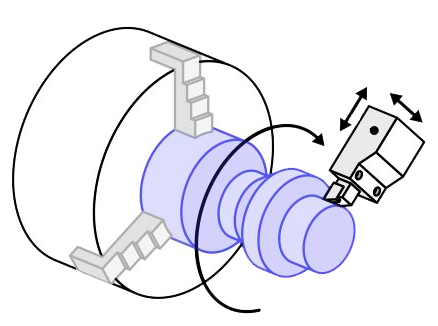

CNC Turning:

With elimination of human error, there is a guaranteed execution of exact measurements from the CAD files. It is a precise, efficient machining process of subtracting material from the work piece, working on lathe machine principle.

This method is best when creating repeated symmetrical and cylindrical parts faster and with a high production volume. CNC turning produces parts with high quality and smooth surface finishes.

Other additional CNC turning operations are grooving, knurling, taper turning, parting, threading, and turning( cylindrical and straight).

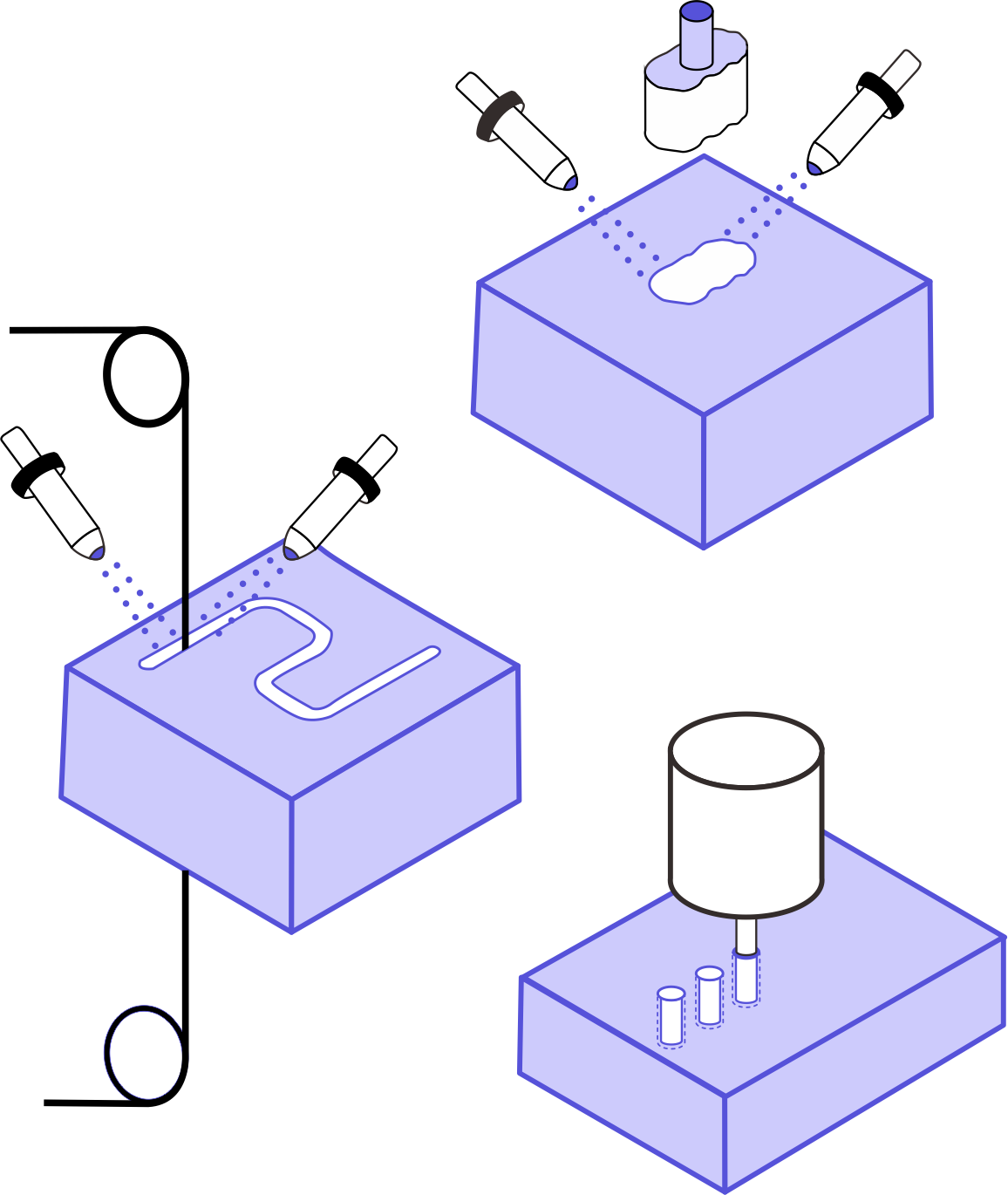

Die Sinking EDM

Die sinking EDM, or Electrical Discharge Machining, is a precision machining process that uses electrical discharges to shape and form metal workpieces, commonly employed in the production of molds and dies.

Wire EDM

Wire EDM is a precise machining technique employing a thin, charged wire to intricately cut through metal, ideal for applications like tool and die manufacturing.

Hole Drilling EDM

Hole Drilling EDM, or small hole drilling EDM, precisely machines extremely small and deep holes.

CNC machining capabilities

Hole Diameters

It is recommended the hole should be the same as the standard bit size. Standard diameter is recommended for high precision holes less than 20 mm.

Recommended depth is 4 x nominal diameter with the typical one being 10 times the nominal diameter and 40 times for the feasible depth.

Precision Tolerances

The standard tolerance limit for CNC machining limit is set around +/- 0.0127 mm (0.005 in.)

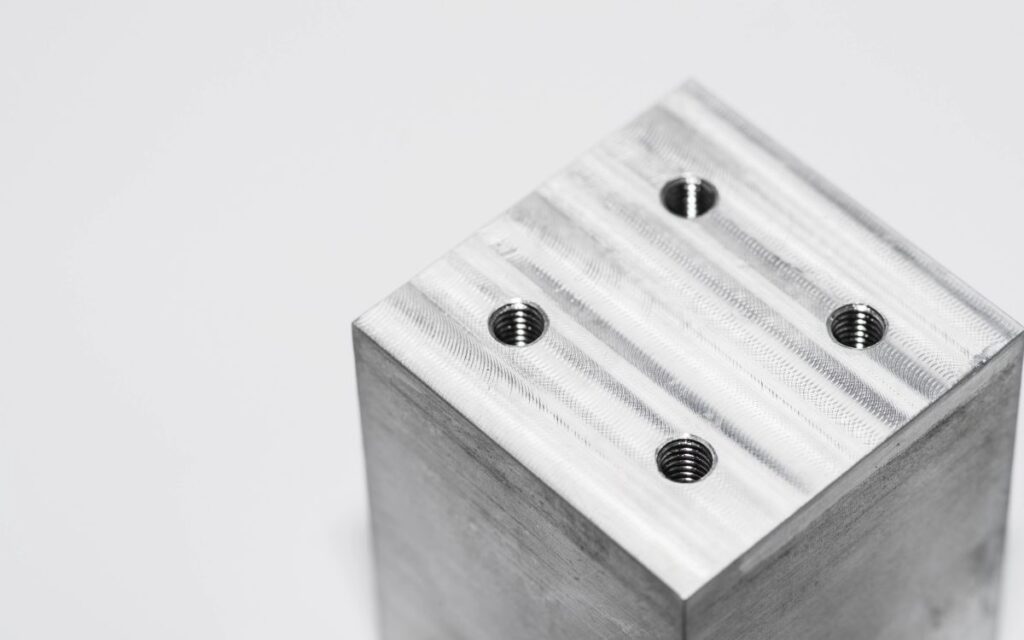

Threads and Tapped Holes

Minimum size is M2 while the recommended is M6 or more with the internal threads being worked on by a tap and die. A minimum length of 1.5 time the nominal diameter is recommended while the most preferable is double the value.

Size

Maximum Part Size: 200 x 80 x 100 cm

Minimum Part Size: 4×4 mm

Delivery Time

3 Working Days

CNC Machining Materials

Metals

Aluminum

Brass

Copper

Stainless Steel

Steel Alloy

Titanium

Plastics

ABS

Acetal

CPVC

Delrin (POM)

HDPE

LDPE

Nylon

PEEK

PEI

PET

PMMA

Polycarbonate

Polypropylene

PPSU

PS

PSU

PTFE

PVC

We can source any other material on request, Get A Quote Now.

CNC Machining Tolerance

If not otherwise specified on the technical drawing, all parts will be machined to ISO 2768 tolerance standards below. Generally you can

choose ISO 2768-m, ISO 2768-f or specify more tighter tolerances in your 2D technical drawings.

Linear Dimension

Limits for nominal size

F (fine)

M (medium)

C(coarse)

V(very coarse)

0.5mm to 3mm

±0.05

±0.1

±0.2

–

Over 3 up to 6

±0.05

±0.1

±0.3

±0.5

Over 6 up to 30

±0.1

±0.2

±0.5

±1.0

Over 30 up to 120

±0.15

±0.3

±0.8

±1.5

Over 120 up to 400

±0.2

±0.5

±1.2

±2.5

Over 400 up to 1000

±0.3

±0.8

±2.0

±4.0

Over 1000 up to 2000

±0.5

±1.2

±3.0

±6.0

Angular Dimension

Limits for nominal size

F (fine)

M (medium)

C(coarse)

V(very coarse)

Up to 10

±1º

±1º

±1º30′

±3º

Over 10 up to 50

±0º30′

±0º20′

±1º

±2º

Over 50 up to 120

±0º20′

±0º20′

±0º30′

±1º

Over 120 up to 400

±0º10′

±0º10′

±0º15′

±0º30′

Over 400

±0º50′

±0º20′

±0º10′

±0º20′

CNC Machining Surface Finishes

CNC machining finishes play a major role in determining how the end product will look like. Some varieties of surface finishes are textured surface, matte, smooth and brushed surface. The type of surface finish is determined by the design type. The main aim of surface finishing is to increase a parts durability.

Name

Description

Materials

Color

Texture

As machined

The CNC machined parts have minor tool marks and average roughness. This finish is mostly as desired from the machine.

All Materials

N/A

N/A

Polishing

The aim is to make the part shiny, reflective and and aesthetically appealing. This method gives the part a mirror like look.

N/A

Shiny

Brushed

A brushed finish is a surface treatment achieved by brushing a material with abrasive tools, resulting in a textured appearance often applied to metals.

N/A

Satin

Bead Blast

Bead blasting propels fine beads at high velocity onto a workpiece to achieve a smooth, clean surface or remove contaminants and coatings.

N/A

Satin

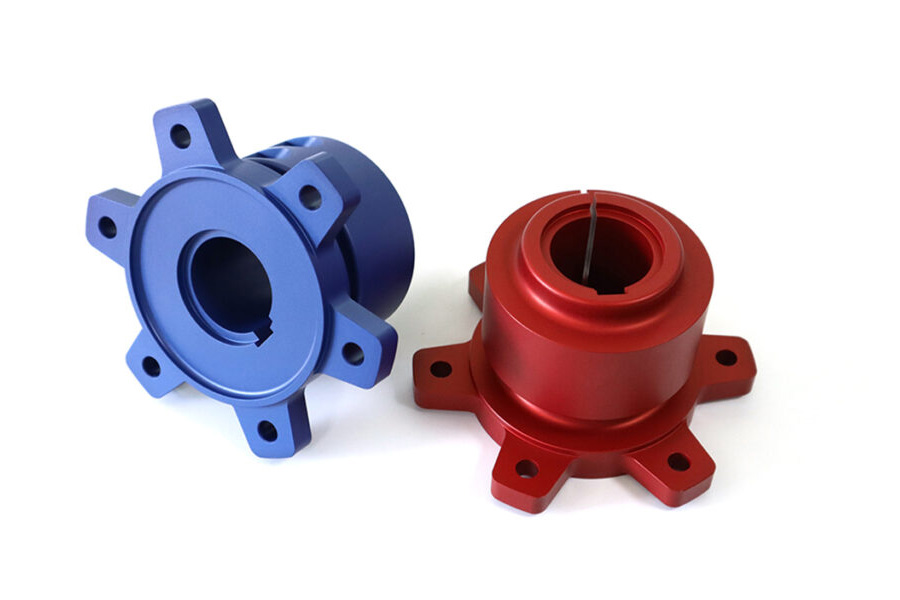

Anodized (Type II Or Type III)

Anodization finishing is a process in which the surface of a metal, typically aluminum, undergoes controlled oxidation to form a protective layer, enhancing corrosion resistance and providing a decorative or functional coating.

Clear,

Black,

Grey,

Red,

Blue,

Gold

Smooth, matte finish.

Powder coated

Anodization finishing is a process in which the surface of a metal, typically aluminum, undergoes controlled oxidation to form a protective layer, enhancing corrosion resistance and providing a decorative or functional coating.

Clear,

Black,

Grey,

Red,

Blue,

Gold

Smooth, matte finish.

Our Customers speak for us